Zhejiang Jhenten Machinery Co.,Ltd.

Name:Henson.Zeng

Phone:+86 15957782988

Tel:+86 577-86867777

Email:info@jhenten.com

No.808 Haitong Road, Binhai Development Zone, Wenzhou City

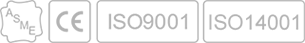

Process System Skid

Vacuum deaerators

Our vacuum deaerators are used for continuous and automatic removal of air and other gases from liquid, viscous and pasty products.

Introduce

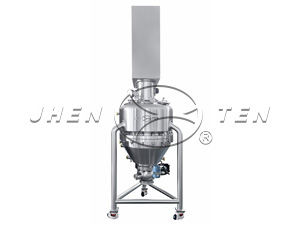

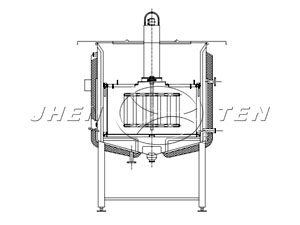

Our vacuum deaerators are used for continuous and automatic removal of air and other gases from liquid, viscous and pasty products. When liquid products are processed, air and unwanted gases are often mixed into the product. These gases often cause problems such as oxidation, discoloration, inconsistencies, and difficulty filling. Jhenten's equipment can alleviate these problems by efficiently and economically removing entrained gas, we work by creating a very high vacuum (up to -0.95barG) in the chamber, and then loading the product. In most cases, the product can be quickly sucked into the chamber by vacuum, forming a fine layer of product, which breaks the air bubbles in the product, and then degasses. In addition, we have added sieve holes in the equipment to make the separation of air and product particles better.

Application

Food products, cosmetics and chemicals etc. It can be sauces, fruit pulp, cosmetic creams, syrups, PVC dispersions, lubricants, car polish, shower gels, paraffin and penicillin emulsions, ice creams, adhesives, etc.

Advantages

◆Fully automated for "standalone" operation with PLC control cabinet

◆Explosion-proof construction for flammableproduct

◆Pneumatic or electrical lifting or loweringof the top cover

◆Speed of distributor plate infinitelyadjustable

◆Special level control for sensitive products

◆Various vacuum systems available

◆Higher pressure discharge pump

◆Sanitary designs

◆Jacket for heating or cooling

◆Special materials of

Design Parameter

Design pressure | According to customers’ requirement(Full vacuum~1.0Mpa) |

Design temperature | According to customers’ requirement(0℃~250℃) |

Material

kettle liner | 304、316L |

kettle outlet layer | 304 |

Legs | 304 |

Connection

In-outlet | Tri-clamp,Flange |

Surface Finish

Finish type | echanical/electrolytic polishing, sand blasting, pickling |

Polishing precision | Inner surface Ra≤ 0.4μm, Outside surface Ra≤ 0.6μm |

Date Specifications

Model | Working volume | Light liquid | Viscous product | Highly viscous product | Total power | L | W | H | H1, with open lid | Weight |

Flowrate(Liter/hr) | ||||||||||

(Liter) | (<300cPs) | (<5,000cPs) | (≥5,000cPs) | (kW)(*) | (mm) | (mm) | (mm) | (mm) | (kg) | |

JTVDS-25 | 25 | 1,500 | 900 | 300 | 5.2 | 1,300 | 800 | 1,710 | 1,850 | 280 |

JTVDS-65 | 65 | 4,000 | 2,500 | 800 | 7.4 | 1,900 | 1,200 | 2,050 | 2,390 | 500 |

JTVDS-125 | 125 | 8,000 | 5,000 | 1,600 | 10 | 2,055 | 1,370 | 2,060 | 2,450 | 1,500 |

JTVDS-300 | 300 | 15,000 | 9,000 | 3,000 | 17 | 2,100 | 1,400 | 2,240 | 2,490 | 2,000 |

JTVDS-550 | 550 | 20,000 | 12,500 | 4,000 | 28 | 2,300 | 1,525 | 2,465 | 2,750 | 2,800 |

JTVDS-1200 | 1,200 | 30,000 | 18,000 | 6,000 | 40.5 | 2,755 | 1,850 | 2,875 | 3,875 | 3,500 |

Welcome to send an online inquiry! If you have any suggestions or questions about our products, you can Email us.info@jhenten.com, also feedback through this inquiry; we will reply to you within 24 hours. (Monday to Friday, 9:00-17:30)

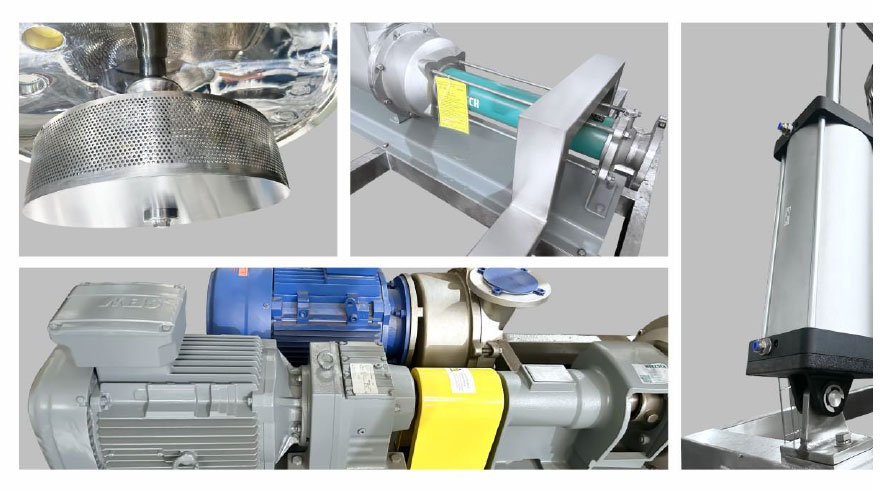

Other Products

We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.