We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.

Hot keywords:

Multi-functional extraction tank | Hemo Oil extract | CBD oil extraction equipment | Alcohol distillation tower | Scraper concentrator | Single-effect alcohol evaporator | Double effect concentrator | Ethanol recovery equipment | Hydrocarbon extract | ASME Certified reactor | Hemp oil crystallizatio | Low temperature ethanol extract | Ethanol precooling tank

Zhejiang Jhenten Machinery Co.,Ltd.

Contact: Henson.Zeng

Phone: +86 15957782988

Tel: +86 577-86867777

Email: info@jhenten.com

No.808 Haitong Road, Binhai Development Zone, Wenzhou City

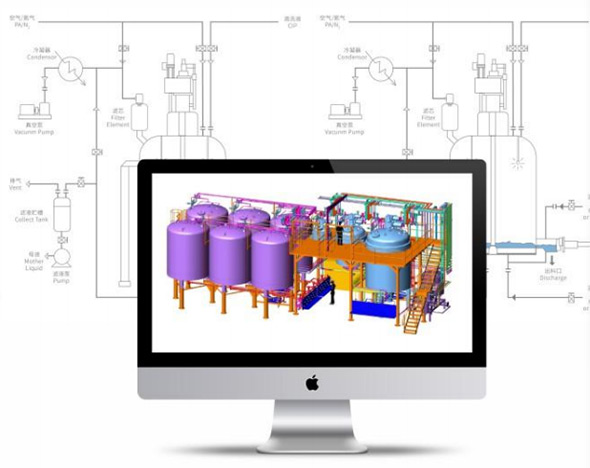

Jhenten team members from the pharmaceutical and chemical industry production, design, and institute expert team, is the industry's senior professionals, our involved fields mainly cover:

process, automation, machinery, electrical, verification documents and project management, we can complete the basic and detail engineering .

Basic-Engineering

Basic-Engineering

• Design of process components

• Process description

• Material and energy balance

• Process flow sheets, process and instrumentation diagrams (P&ID)

• Equipment lists and specifications

• General layouts

• Cost and schedule planning

Detail-Engineering

• Layout design in 2D and 3D

• Piping engineering including isometrics

• Planning and design of measurement and control technology

• Development of process und program sequences

• Supervision/coordination of planning of electrical engineering / control systems

• Supervision/coordination of construction planning

Tradition of continuous innovation

The history of Jhenten can trace to 1986. The welding & polishing was from pure manual to full automatic,polishing from dry to water. Our company insists in continuous innovation, this kind of spirit guides the way forward. And it hasn't changed till today.

modular system:

In the main produce process of biopharmacy, food & beverage and fine chemical engineering, modular system can reduce the high-cost caused by cross contamination and Human error. Jhenten usingAUTOCAD and 3D software for professional design, providing modular system solution and technical services. We also provide complete FDA and GMP authentication support, meet the requirements of customers for the high quality of the products.

• Purified water injection system

• CIP/SIP system

• Liquid mixing system

• Avoid error burden system online

Promise of cleaning:

• Edges and corners design to round

• Surface polished evenly. Can provide the inspection report

• No gap or sag

• Seamless components and accessories

Promise of cleaning:

• Edges and corners design to round

• Surface polished evenly. Can provide the inspection report

• No gap or sag

• Seamless components and accessories

Surface cleaning

The standard of cleaning vessel is very pivotal, cleaning requirement should be considered during design stage. No dead Angle design must be considered to ensure the effect of cleaning and sterilization.

Jhenten using the lasted computer-assisted method to process computer simulate for the spray range of CIP cleaning ball when design cleaning vessel, to ensure the cleaning effect cam meet customers' need. Also it using least cleaning solution to reduce user's operating costs. The outer surface of the tank cleaning is also important. Jhenten machine consider not only the beautiful appearance, but also the practicality when designing the tanks. Outside surface must be easy to clean, and must ensure the safety of the operator.

R&D Dept Members:8 people

We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.