Zhejiang Jhenten Machinery Co.,Ltd.

Name:Henson.Zeng

Phone:+86 15957782988

Tel:+86 577-86867777

Email:info@jhenten.com

No.808 Haitong Road, Binhai Development Zone, Wenzhou City

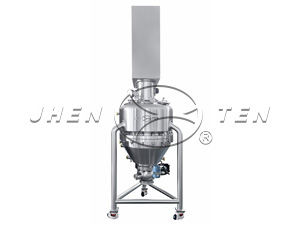

Fermenter

Biological Fermentation Tank

Model: JTRSF

Brand: JHENTEN

Biological Fermentation Tank be designed, manufactured and inspected in accordance with the pressure vessel standard(GB150-2011) and the steel welded atmospheric pressure vessel standard(NB/T 47003.1-2009) , strictly meet to GMP certificate requirements.

Biological Fermentation Tank be designed, manufactured and inspected in accordance with the pressure vessel standard(GB150-2011) and the steel welded atmospheric pressure vessel standard(NB/T 47003.1-2009) , strictly meet to GMP certificate requirements.

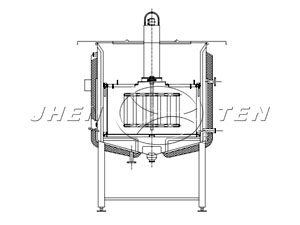

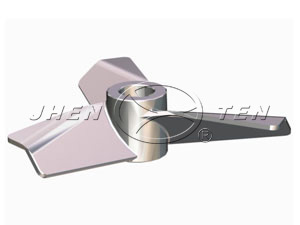

Biological fermentation tank use vertical circular tanks, upper portion is standard elliptic or butterfly head, bottom is the standard or elliptic, butterfly head conical head, tank wall adopts circular arc transition, no dead corner, easy to clean;Can optional configure various forms of jacket, tanks and the head is equipped with the jacket and insulation layer, the top configuration of mechanical stirring .

Tank Optional Configuration

Biological Fermentation Tank Optional Configuration: sterile air filter, thermometer (digital display type or dial), PH meter, pressure gauge, steam sterilization port, sight glasses, sanitary manhole, in-outlet ,CIP universal rotating cleaning ball, liquid level meter and liquid level self-control system (bearing module, non-contact ultrasonic, static pressure transmitting device), etc.,or configured according to customers' requirements.

Application

• Suitable for medicine, biological products, dairy products, food, brewing, beverage, personal care products industries etc.

Feature

• There are 600L~20000L varietys of specifications, it can be designed, customized according to the customers' requirements.

• Jacket can put into steam (or hot water), jacket is divided into coil jacket,full jacket, dimple jacket; Jacketed outside covered with insulation layer, insulation material is rock wool (keep warm) or PU (keep cold).

• Connector use fast installation chuck(clamp), inner tank use SS304 or SS316L, the inner surface mirror polishing Ra≤0.28μm~0.6μm, outer surface can be polishing, wiredrawing ,sandblasting according to customer's requirement.

Design Parameter

Designpressure | 0.02MPa~1.0MPa |

Designtemperature | According tothe customers' requirements(0℃~160℃) |

Material

Inner | 304、316L |

Insulation |

Rockwool(keepwarm) |

Feet | 304 |

Surface Finish

Finishtype |

Mechanical polishing, electrolyticpolishing, |

Polishing precision |

Inner surface Ra≤0.4μm |

Connection

In-outlet | Tri-clamp,Flange |

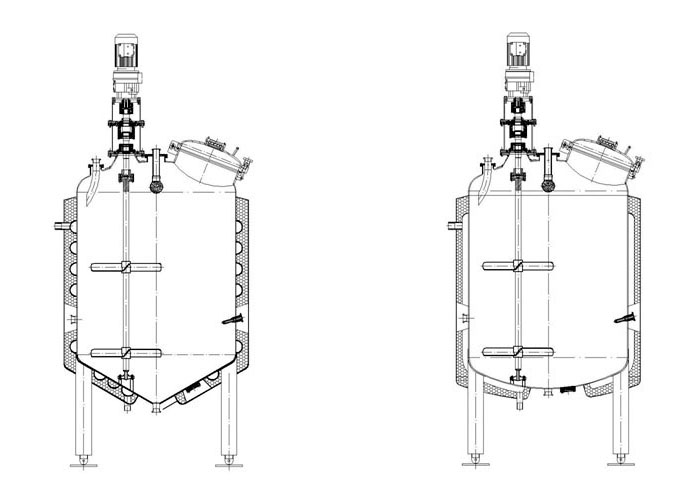

Coil jacket type Biological Fermentation Tank(斜叶桨式搅拌桨、conical bottom head) Full jacket type Biological Fermentation Tank(斜叶桨式搅拌桨、elliptical bottom head)

Normal Model And MainTechnical Parameters

Parameters | Model | JTRSF—600 | JTRSF—1000 | JTRSF—2000 | JTRSF—3000 | JTRSF—4000 | JTRSF—5000 | |

Effectivevolume:L | 600 | 1000 | 2000 | 3000 | 4000 | 5000 | ||

Barrel | Diameter:mm | Φ900 | Φ1100 | Φ1300 | Φ1600 | Φ1700 | Φ1800 | |

Height:mm | 900 | 1000 | 1500 | 1500 | 1800 | 1800 | ||

Mixing | Motor power:kW | 1.1 | 1.5 | 2.2 | 2.2 | 3 | 4 | |

Mixing work RPM:r/min | 60(斜叶桨式)(The design canbe adjusted according to customers’ usage) | |||||||

JTRSF—6000 | JTRSF—8000 | JTRSF—10000 | JTRSF—12000 | JTRSF—15000 | JTRSF—20000 | |

6000 | 8000 | 10000 | 12000 | 15000 | 20000 | |

Φ1900 | Φ2000 | Φ2200 | Φ2400 | Φ2600 | Φ2800 | |

2000 | 2200 | 2400 | 2500 | 2700 | 3000 | |

4 | 5.5 | 7.5 | 7.5 | 11 | 11 | |

60(斜叶桨式)(The design canbe adjusted according to customers’ usage) | ||||||

Theabove-mentioned data is the standard ,for reference only. it can customizeaccording to customer's requirements. | ||||||

Welcome to send an online inquiry! If you have any suggestions or questions about our products, you can Email us.info@jhenten.com, also feedback through this inquiry; we will reply to you within 24 hours. (Monday to Friday, 9:00-17:30)

Other Products

We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.