Zhejiang Jhenten Machinery Co.,Ltd.

Name:Henson.Zeng

Phone:+86 15957782988

Tel:+86 577-86867777

Email:info@jhenten.com

No.808 Haitong Road, Binhai Development Zone, Wenzhou City

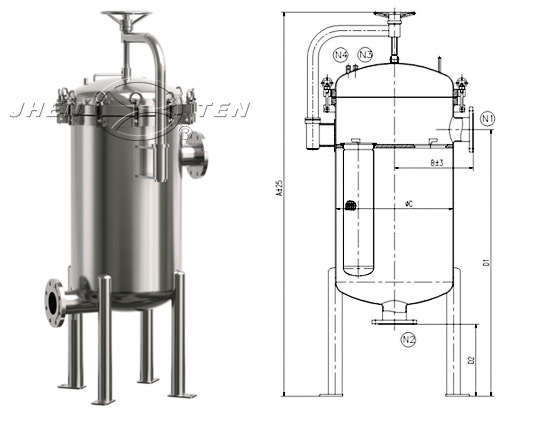

Bag Filtration

Multi Bag Filter Housing

Model: JTGDS

Brand: JHENTEN

High Flow Bag Filter Housing

JTGDS Multi bag filter housing, for some coarse filtration and pre filtering process

JTGDS Standard No. 01 bag or 02 bag, the standard model for 2 ~ 12 bags, the maximum production of customized to 24 bags, can basically meet the requirements of various types of flow

Feature

Large flow, Long service time.

Compact design,can reduce the area of space, while reducing the loss of liquid

Side entry and bottom out , it ensure liquid medium can be completely discharged, the tangential position outlet made pollution thoroughly, is convenient to operating

The unique three-point clamp device to ensure good sealing, avoid liquid side leakage

The filter housing can use swing arm and the eyebolt or quick-open design,can operating conveniently and economical.

Application

Food and beverage; bio engineering and pharmaceutical; petrochemical andchemical; automobile manufacturing; petroleum and natural gas; electronic andnatural gas; coating, paint, printing ink; nuclear power and thermal power andwaste water filtration; liquid and gas purification of liquid and gas.

Surface Finish

Finish Type | Mechanical polishing, Electrolytical polishing, sand blasting, pickling |

polishing precision | IInner surface Ra≤0.6μm , Outside surface Ra≤0.8μm. |

Basket 0.6μm |

Operating Conditions

Max Operating pressure | 1.0MPa |

Max Operating Temp. | 150℃ |

Material

Shell | 304, 316L, SAF2507, |

Eyebolt | 304 |

Stabilizer blade | 304 |

O-ring | EPDM, PTFE, Viton, Silicone |

Connection

Connection for shell | Flange |

In-outlet N1, N2 |

Flange, Quick-open, |

Pressure gauge (optional) | 1/2”Female thread |

Vent valve (optional) | 1/2” Male thread |

Structure

Dimension Parameters | 2pcs | 3pcs | 4pcs | 5pcs | 7pcs |

2#Bag | |||||

A: Total height | 1180 | 1915 | 2030 | 2043 | 2132 |

B: The distance from inlet to center | 300 | 325 | 359 | 378 | 439 |

C: Diameter | Φ400 | Φ450 | Φ500 | Φ550 | Φ650 |

D1:The height from inlet to ground | 1330 | 1350 | 1423 | 1439 | 1480 |

D2:The height from outlet to ground | 300 | 350 | 400 | ||

In-outletN1, N2 dimension | 4” | 5” | |||

Maxflow, m3/h | 80 | 120 | 160 | 200 | 280 |

The above-mentioned data is the standard, it can customize according tocustomer's requirements.

Selection Table

[Qty. of Bag Filter] | [Model of Bag Filter] | [Shell Material] | [In-outlet connection] | [O-ring] | ||

JTGDS | 3P | 2S | 4 | F | E | |

2P=2pcs | 7P=7pcs | 1S=1# Bag:Φ180 x 430 | 4= 304 | F= Flange | E=EPDM | |

3P=3pcs | 9P=9pcs | 2S=2# Bag:Φ180x 810 | 6= 316L | K= Tri-clamp | P=PTFE | |

4P=4pcs | 12P=12pcs | L= Thread | V=Viton | |||

5P=5pcs | S=Silicone | |||||

Welcome to send an online inquiry! If you have any suggestions or questions about our products, you can Email us.info@jhenten.com, also feedback through this inquiry; we will reply to you within 24 hours. (Monday to Friday, 9:00-17:30)

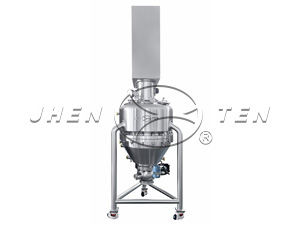

Other Products

We focus on the sanitary pressure vessels, process tanks and modular system design and manufacture.