Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

·Superior Quality: Utilizes vacuum low-temperature evaporation with short residence time, preserving product quality to the greatest extent.

·Energy Efficiency: Supports multi-effect evaporation or steam recompression technology, significantly improving energy utilization.

·Simplified Control: Rapid response and streamlined automation enable easy process management.

·Operational Flexibility: Features rapid startup, seamless switching between production and cleaning modes, and adaptability to varying conditions.

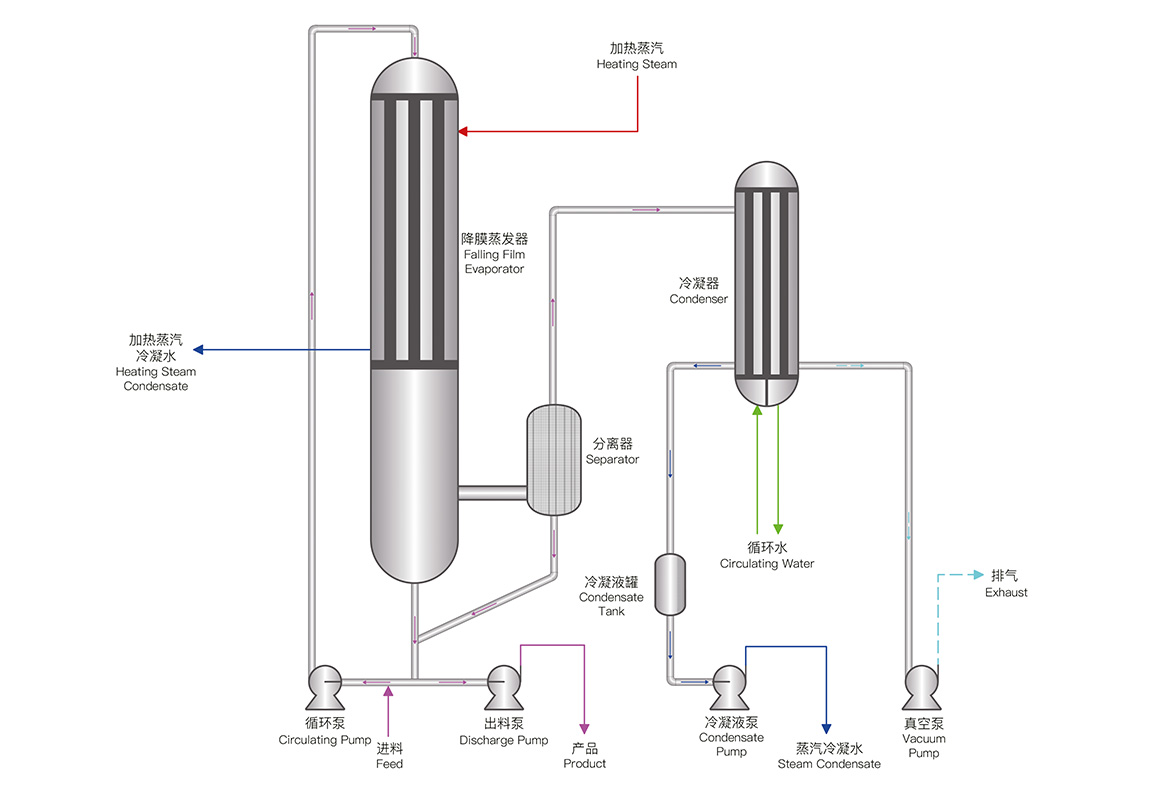

Adopts a vertical shell-and-tube heat exchanger design, integrated with a centrifugal separator to achieve highly efficient vapor-liquid separation.

Concentrated liquid enters from the top of the heating tubes and flows downward along the inner walls under gravity, forming a thin film. External heating induces boiling and partial evaporation of the liquid film. The generated vapor accelerates the downward flow of the liquid film. In the lower section of the tube bundle and the centrifugal separator, vapor is separated from the remaining liquid.

To prevent localized dry walls and scaling, a specialized liquid distributor is installed at the evaporator top to ensure uniform wetting of heating surfaces, particularly in the lower tube sections. Wetting efficiency can also be improved by extending heating tubes, partitioning the evaporator chamber, or implementing product recirculation.