Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

·Strong Adaptability: Handles high-viscosity, crystallization-prone, scaling-prone, and heat-sensitive materials.

·Efficient Heat & Mass Transfer: Thin liquid film on the cylinder wall maximizes heat transfer area and coefficient.

·Operational Flexibility: Adjustable scraper speed, feed rate, and heating medium temperature to meet diverse requirements.

·Easy Maintenance: Simplified disassembly and cleaning reduce downtime and upkeep costs.

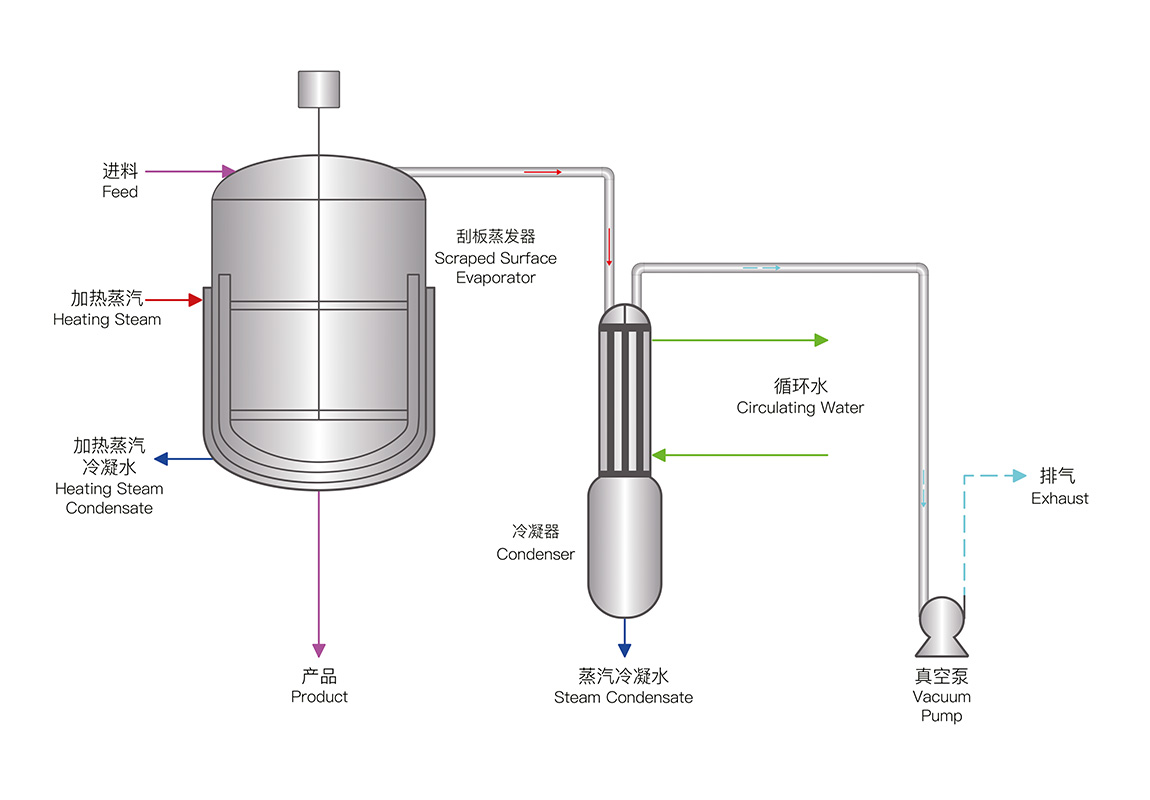

Comprises a heating jacket, evaporation cylinder, scraper assembly, and liquid collection system. The heating jacket surrounds the evaporation cylinder, while the scraper assembly inside the cylinder rotates via a central shaft.

Material enters the evaporator top via feed pipes and is uniformly distributed along the inner wall by gravity and rotating scraper blades, forming an even film. Heating via steam or thermal media in the jacket promotes rapid evaporation. Continuous scraping action renews the film surface, enhancing heat transfer. Generated secondary vapor exits through the top for condensation, while concentrated product flows downward and discharges through the bottom outlet for continuous operation.