Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

·Energy Efficiency: Multi-stage design reuses secondary steam, drastically reducing operational costs.

·Gentle Evaporation: Low-temperature, staged evaporation protects heat-sensitive materials (e.g., food, pharmaceuticals).

·Adaptability: Handles high-viscosity, scaling-prone, and high-solid-content solutions.

·Automated Control: Integrated PLC system monitors and adjusts temperature, pressure, concentration, and other parameters in real time.

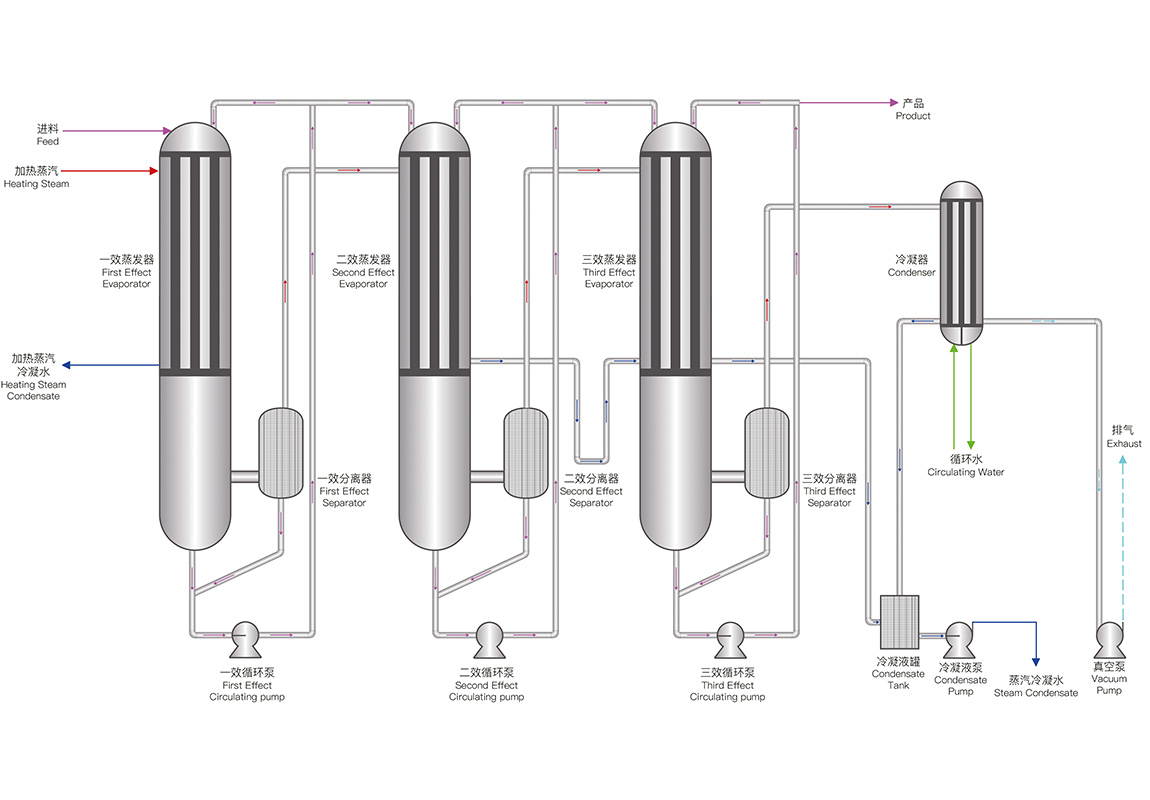

Comprises preheaters, evaporators, separators, condensers, vacuum systems, and control systems. The evaporators are connected in multiple stages (effects), each equipped with a heating chamber and separation chamber. Piping and valves enable efficient circulation of materials and steam across stages.

Preheated material enters the first effect evaporator, where partial evaporation occurs using primary steam. Subsequent effects utilize secondary vapor from the previous effect as heat sources, progressively lowering operating pressures to enable low-temperature evaporation. This cascading energy reuse minimizes thermal degradation of heat-sensitive components. Final concentrate discharges from the last effect, with condensed vapor recovered to significantly reduce energy consumption.