Welcome to the 'Online Message' section! If you have any suggestions or questions about our products, please feel free to provide us with feedback through this section.

We will reply to you within 24 hours.

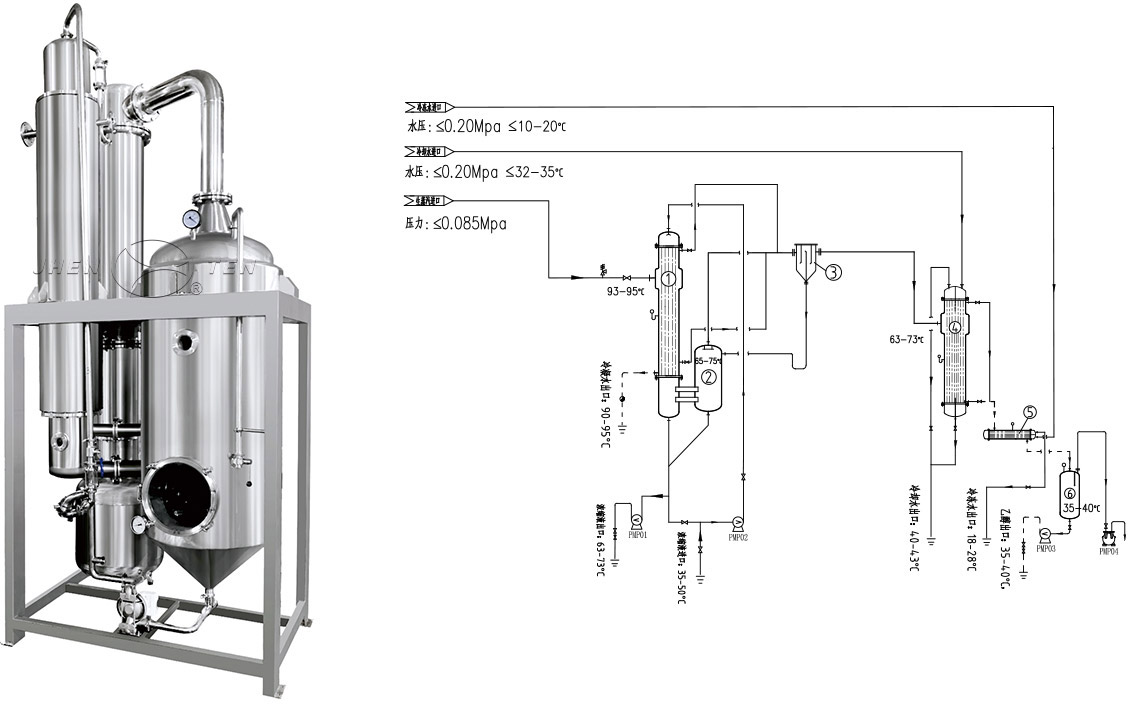

Full closed process, fast and low temperature evaporation;

Heating fast with high efficiency and hard to produce the deposit on the machine's inside wall;

1.Full closed process, fast and low temperature evaporation;

2 Heating fast with high efficiency and hard to produce the deposit on the machine's inside wall;

3.Large scale of the concentrate ratioas the products between the different effecs can recycle separately, so the concentrate ratio can be regulated in large scale;

4.The machine attach with spraying ball and self CIP system.

Single effect evaporator: this equipment adopts down falling film evaporation type. construction: evaporator, separator, condenser etc. Use popularly used for concentrating and dehydration in food, biology engineering, pharmacy,organic solvents and chemistry etc. Automatic control: manual operated and full auto control.

Project | SJM-100 | SJM-200 | SJM-400 | SJM-600 | SJM-800 | SJM-1000 | SJM-1200 |

Ethanol evaporation capacity(kg/h) | 100 | 200 | 400 | 600 | 800 | 1000 | 1200 |

A. Heating source medium:steam | |||||||

Raw steam pressure (Mpa) | 0.085 ( Absolute pressure) | ||||||

Steam heat consumption (kcal/h) | 30000 | 60000 | 120000 | 180000 | 240000 | 300000 | 360000 |

B. Heating source medium:heat transfer oil | |||||||

Heat transfer oil inlet and outlet temperature (℃) | 120—130/100—110 | ||||||

Heat consumption of heat transfer oil (kcal/h) | 31000 | 62000 | 124000 | 186000 | 248000 | 310000 | 372000 |

Working pressure of heat transfer oil (Mpa) | 0.15—0.20 | ||||||

Evaporation temperature (℃) | 65—75 | ||||||

Ethanol discharge temperature (℃) | 35—40 | ||||||

Concentrate discharge temperature (℃) | 63—73 | ||||||

Vacuum (-Mpa) | 0.065—0.077 | ||||||

Heating area (㎡) | 3.0 | 6.0 | 12 | 18 | 24 | 30 | 36 |

Condensing area (㎡) | 6.0 | 12 | 24 | 36 | 48 | 60 | 72 |

Condenser workingpressure (Mpa) | 0.20—0.25 | ||||||

Cooling area (㎡) | 2.0 | 3.0 | 4.0 | 5.0 | 6.0 | 8.0 | 10 |

Cooler working pressure (Mpa) | 0.15—0.20 | ||||||

Cooling water circulation (t/h) | 3.8 | 7.6 | 17 | 24 | 32 | 39 | 47 |

Cooling water workingpressure (Mpa) | 0.20—0.25 | ||||||

Cooling water inlet and outlet temperature (℃) | 32—35/40-43 | ||||||

Chilled water consumption (Kcal/h) | 1500 | 3000 | 6000 | 9000 | 12000 | 15000 | 18000 |

Chilled water inlet and outlet temperature (℃) | 10—20/18—28 | ||||||

Chilled water workingpressure (Mpa) | 0.15—0.20 | ||||||

Total installedpower (kw/h) | 3.75 | 5.55 | 6.6 | 8.7 | 10.7 | 12.5 | 14.25 |